If you are a manufacturer and especially if you are exporting for the first time, you should have a checklist of points to consider before packing your cargo.

Here are 5 main points you should consider before packing your cargo.

While you cannot pack double the 20′ cargo weight into a 40′ container, you can definitely pack more than double the 20′ cargo volume into a 40′ container.

1) Use the right type of CTU (Cargo Transport Unit)

By CTU, here I am referring to a freight container. As I have explained in my previous article, there are various cargo types and packing methods in container shipments.

It is of utmost importance that you use the correct container size/type for the packing of your cargo.

Questions such as below, although incorrect, are quite common and need to be properly understood.

20′ containers are designed to carry more weight than voluminous cargo. Example – Minerals, Metals, Machinery, Sugar, Paper, Cement, Steel Coils all of which are heavy cargoes.

40′ containers are designed to carry voluminous cargo rather than heavy cargo. Example – Furniture, Steel Pipes, Paper scrap, Cotton, Tobacco all of which are voluminous cargoes.

While you cannot pack double the 20′ cargo weight into a 40′ container, you can definitely pack more than double the 20′ cargo volume into a 40′ container.

Of course, the type of container used is directly related to the type of cargo that you intend to ship..

For example, if you are exporting food products, you may require a food-grade container. If you make a specific request for such a container from the shipping line, they may be able to provide the same (usually at an extra preparation cost) to you.

This then brings us to the “condition” of the CTU.

If the container that you are using to pack your cargo is not in a good condition, you are opening yourself up to possible cargo damage, loss, claims, etc.

One of the most frequent spats between an exporter and a shipping line relates to the condition of a container that the exporter picks up for packing. People have been varied in their opinions on who is liable.

In the normal course of business, the shipping line is expected to release a clean, sound, dry, and cargo-worthy container from their empty storage depot to the transporter of the exporter. The container depot has a responsibility to ensure that the shipping line’s instructions are followed.

On the other side, the transporter has the responsibility to check if the container that is released from the depot will suit the exporter’s needs.

General items to be checked here would include (but not limited to)

- the empty container received is clean, dry, and free from any unusual smells, stains on the floorboard

- no roof holes

- the doors shut tight and without gaps

- the lock rods close and lock properly

- the slots for the seals are present and usable

- floorboard is not cracked or broken

- These quick checks if done, will prevent any major damage or loss claims at a later stage.

3) Use the correct shipping line’s container – As silly as it may sound, this is also a major issue faced by some exporters. So if you are an exporter who exports a big volume of cargoes, sometimes packing up to 20-30 containers in a day to various destinations, using the containers of various shipping lines, it is highly possible that you/your packing depot could cross-pack some cargo.

Adding to this confusion is also the fact that many shipping lines lease containers from the same leasing company so the prefixes may be the same (like MSC and Maersk line both leasing TEXU (Textainer) containers) and you or your packing warehouse may incorrectly allocate one line’s container for packing cargo to a destination to which that shipping line does not service.

For example, allocating and packing a container under the control of ZIM Lines of Israel with cargo meant for IRISL Line to Iran.

4) Documentation – Another crucial area of the shipping process which you must understand, understand, and understand is the documentation process. Documentation related to the cargo that you are about to pack and ship.

General items to be checked here would include (but not limited to)

Does your cargo require any permits to be loading and discharged? Is your cargo allowed for discharge at the destination?

Although you might think the buyer has ordered the goods and he has checked above, in a lot of the cases, the shipping line will hold you (being the exporter/booking party) liable for any cargo that may be abandoned at the destination due to such issues.

Is my cargo hazardous, and does it require a dangerous goods declaration?

Is my packing list correct and reflects the correct cargo weights as there are different weights used in shipping and there are consequences due to container weight misdeclaration.

Also bear in mind the SOLAS VGM regulations and if you are using Method 2, then you need to have those weight documentation handy.

If you are about to pack Out Of Gauge (OOG) Cargo then you need to ensure that your OOG transport permits, escorts, etc. are ready and have been secured either by you or your transporter.

Ensuring that your documentation is all in order even before you pack will ensure that nothing is forgotten as it would be quite expensive to unpack/repack any cargo due to improper or incorrect documentation.

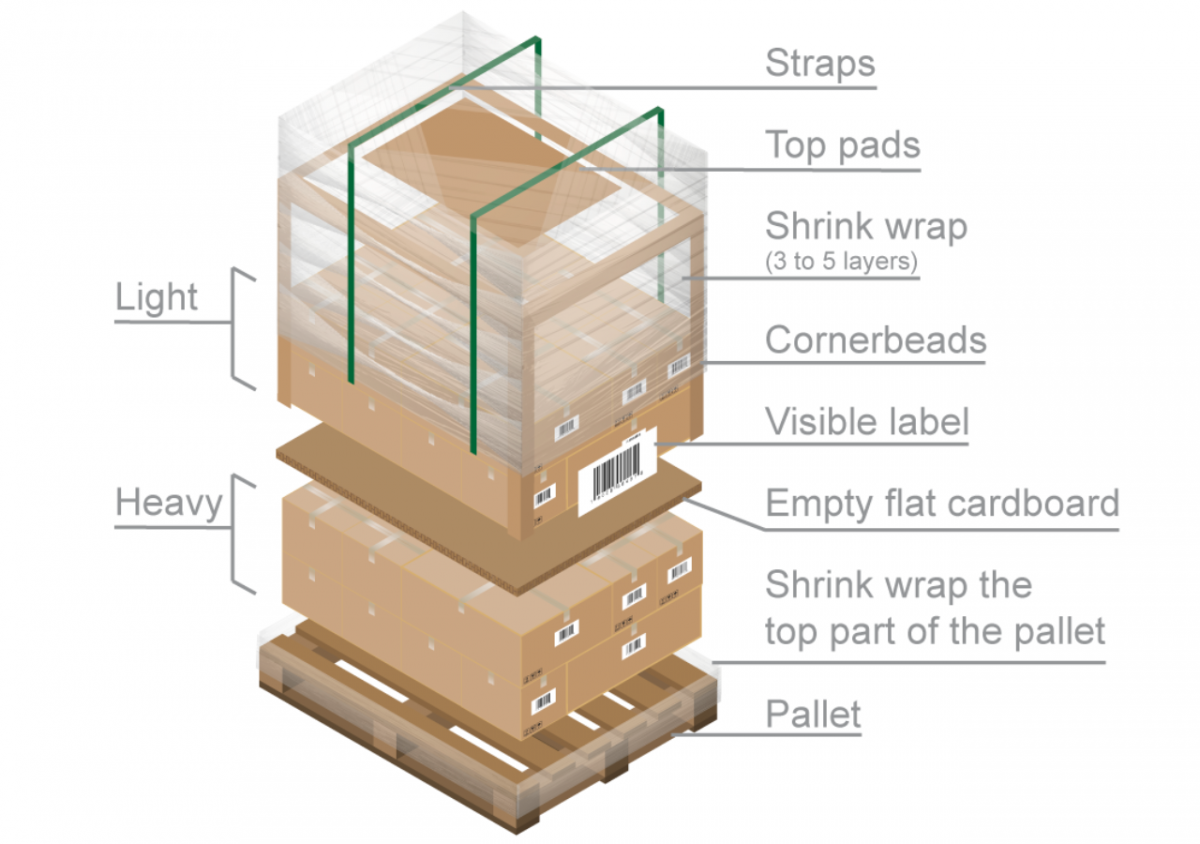

5) Pack it properly will ya – even if you have checked and satisfied yourself with all the above points, one vital point remains and that is to “pack your cargo properly”. Yes, again it may sound like a no-brainer, but a lot of issues such as accidents, cargo damage, etc happen at sea and on the shore due to improper packing of cargo.

Points to consider before packing your cargo

In one of my previous posts, I wrote about the need to pack your cargo properly, and in that post, I have shown a slideshow that shows some pictures of cargo that has been improperly packed/secured in containers.

This will give you an idea of the damages that happens to cargo and the losses that the shipper or consignee incur, as a lot of them still ship cargo without proper insurance coverage.

NEVER underestimate the importance of Protecting your valuable cargo for shipment. You do not want your cargo arriving at the destination looking like above.

Sorce: https://www.shippingandfreightresource.com/points-to-consider-before-packing-your-cargo/